Industrial

With more than 80 years of experience, Red Gold has an industry-wide reputation for creating the highest quality tomato-based products formulated for the specific needs of our customers.

Industrial Solutions Delivered

The trust that leading national retailers and leading national brands place in us is not taken lightly. Whether your need is national brand emulation or creating an innovative new product that solves an unmet consumer need, Red Gold is ready to deliver.

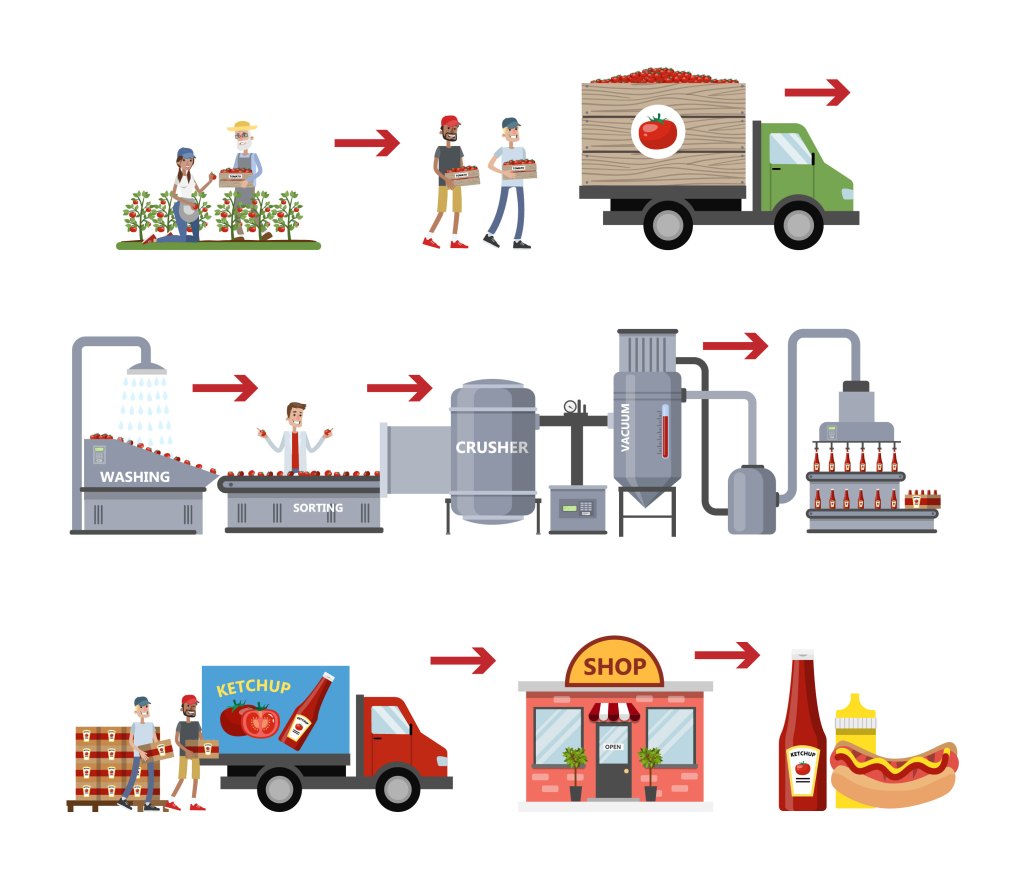

Food Manufacturing Process

1. Harvesting and Transport:Tomatoes are harvested at peak ripeness and transported to a processing plant.

2. Sorting and Washing:Tomatoes are sorted to remove damaged or unripe ones and then washed thoroughly.

3. Blanching and Peeling:Tomatoes are briefly blanched (immersed in boiling water) to loosen the skin, which is then peeled off.

4. Cutting and Preparation:Tomatoes are cut into desired sizes (whole, halved, diced, crushed, etc.) and prepared for packing.

5. Packing:Tomatoes are packed into cans or jars.

6. Pasteurization:Cans/jars are sealed and then heated to kill bacteria and create a vacuum seal.

7. Cooling:Cans/jars are cooled rapidly after heating to prevent spoilage.

8. Labeling and Packaging:Cans/jars are labeled with brand information and nutritional details, and then packaged for distribution.

Superior Quality: A Founding Principle

At Red Gold, we are passionate about our quality. Superior quality is a founding principle, driving us to create award-winning products our customers depend on, and our consumers love. Red Gold works with the top suppliers to source the highest quality raw materials leading to world-class products. From delivery of ingredients and throughout the manufacturing processes, our proprietary quality assurance protocol sets comprehensive safety practices that identify and eliminate potential hazards.

Certifications

Red Gold’s facilities are SQF Food Safety and Food Quality certified, highlighting our dedication to quality. We have capabilities to produce products that qualify for certifications such as USDA, Organic, Non-GMO, Gluten Free, Plant-Based, and Kosher.

From the seed to the grocery store, Red Gold implements world-class processing methods using state-of-the-art technology resulting in superior quality and consistency. Our dedication to continuously improve our processes has made us a leading supplier of tomato-based products.

Solution Providers

Ready to help with your Industrial needs